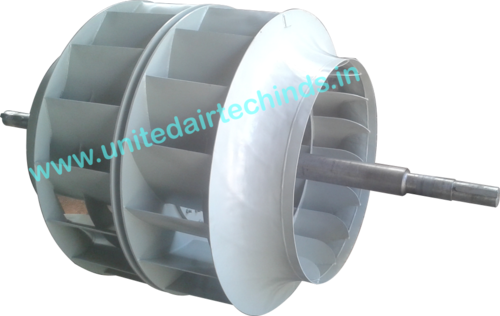

DIDW Spare Impellers

DIDW Spare Impellers Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Nhava Sheva Mumbai

- Supply Ability

- 10 Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Crate Packing

- Main Domestic Market

- Chhattisgarh, Rajasthan, Maharashtra, Gujarat, Andhra Pradesh, Madhya Pradesh, Karnataka, Kerala, Telangana

- Certifications

- ISO 9001:2015

About DIDW Spare Impellers

We are recognized as the prominent manufacturer, exporter and supplier of a wide collection of DIDW Spare Impellers. Offered impellers are manufactured using supreme quality raw material as per the set industry norms. Furthermore, these impellers are used in various industries for the cleaning of cold & hot gases. Available in varied sizes with different foil blades, these impellers can also be customized as per the clients requirements. We offer these DIDW Spare Impellersat cost effective price to the clients.

Features:

- Robustness

- Highly efficient

- Superior aerodynamic performance

- High strength

Technical Specification:

|

Closing Type |

Open |

|

Usage/Application |

Industrial |

|

Model Name/Number |

UNITED |

|

Brand |

UNITED |

|

Impeller Blade Type |

Backward-curved |

|

Material |

As Per Customer Specification |

|

Structure Type |

Single/ Double/ Multistage |

Customizable Design and Robust Construction

DIDW Spare Impellers are crafted from galvanized steel and come in dimensions, flow rates, and capacities designed to match specific customer requirements. Their rugged construction ensures high durability and optimal performance in demanding conditions found in industries such as steel manufacturing and chemical processing. Surface treatments protect against corrosion, extending the impellers operational life.

Reliable Performance for Medium Pressure Applications

These impellers deliver consistent outcomes under medium pressure ranges and varying vacuum or pressure requirements. Their adaptability allows them to integrate seamlessly with electric blowers and other equipment, making them suitable for hot air recirculation and other critical functions. Each impeller undergoes quality assessment for output power, ensuring optimal efficiency per application.

Support, Warranty, and After-Sales Service

As a product from a leading exporter, manufacturer, service provider, and supplier in India, these impellers are offered with a 1-year warranty. Comprehensive support is provided, from initial consultation to after-sales service, ensuring the right fit and optimal operation for every clients unique industrial need.

FAQs of DIDW Spare Impellers:

Q: How are DIDW Spare Impellers customized to fit specific industrial requirements?

A: Each impeller is designed as per the customers technical specifications for dimensions, flow rate, capacity, and motor speed, ensuring seamless integration and maximum efficiency in their intended application.Q: What is the process for ordering a DIDW Spare Impeller?

A: Customers provide their precise operational requirements, such as desired dimensions, pressure range, and application type. The manufacturer then engineers and produces the impeller according to these specifications, delivering a tailored solution.Q: Where are DIDW Spare Impellers typically used?

A: DIDW Spare Impellers are widely used in hot air recirculation systems, chemical process facilities, metal and steel industries, and other sectors requiring medium pressure air movement and high reliability.Q: What warranty and lifespan can customers expect from these impellers?

A: The impellers come with a one-year manufacturers warranty and are constructed for lifelong operation when maintained appropriately, offering long-term service and value.Q: Can the impellers be operated automatically and what is their power source?

A: Yes, the impellers are designed for automatic operation and are powered by electricity, compatible with standard industrial voltages such as 415V.Q: What benefits do these impellers offer to industrial operations?

A: Their robust construction, tailored design, and medium pressure capability enhance efficiency, minimize downtime, and provide maintenance-free, reliable service for a broad range of demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spare Impellers Category

MS Spare Impeller

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Product Type : Other

Color : Siemens Grey

Warranty : 1 year

Power : 380 to 415 Volt (v)

Rubber Coated Impellers

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Product Type : Other

Color : Siemens Grey

Warranty : 1 year

Power : 380 to 415 Volt (v)

Rubber Lined Spare Impellers

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Product Type : Other

Color : Siemens Grey

Warranty : 1 year

Power : 380 to 415 Volt (v)

Centrifugal Blower MS Impellers

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Product Type : Other

Color : Siemens Grey

Warranty : 1 year

Power : 380 to 415 Volt (v)

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry