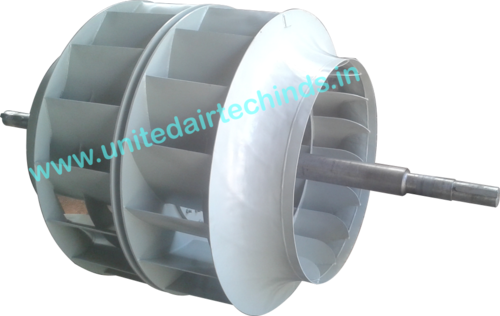

Centrifugal Blower MS Impellers

Price 25000 INR/ Unit

Centrifugal Blower MS Impellers Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Nhava Sheva Mumbai

- Supply Ability

- 10 Sets Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Crate Packing

- Main Domestic Market

- Rajasthan, Chhattisgarh, Maharashtra, Madhya Pradesh, Karnataka, Andhra Pradesh, Telangana, Kerala, Gujarat

- Certifications

- ISO 9001:2015

About Centrifugal Blower MS Impellers

We are recognized as the prominent manufacturer, exporter and supplier of a wide collection ofSpare Impellers. Offered impellers are manufactured using supreme quality raw material as per the set industry norms. Furthermore, these impellers are used in various industries for the cleaning of cold & hot gases. Available in varied sizes with different foil blades, these impellers can also be customized as per the clients requirements. We offer theseSpare Impellersat cost effective price to the clients.

Features:

- Robustness

- Highly efficient

- Superior aerodynamic performance

- High strength

Technical Specification:

|

Closing Type |

Open |

|

Usage/Application |

Industrial |

|

Model Name/Number |

UNITED |

|

Brand |

UNITED |

|

Impeller Blade Type |

Backward-curved |

|

Material |

As Per Customer Specification |

|

Structure Type |

Single/ Double/ Multistage |

Superior Performance for Demanding Industries

Built for diverse applications such as chemical processing, metal and steel manufacturing, and hot air recirculation, the Centrifugal Blower MS Impeller delivers reliable airflow tailored to each industrys intricate needs. The blower combines high efficiency with long operational life thanks to its galvanized, corrosion-resistant surface and industry-specific engineering.

Customized to Meet Your Project Requirements

Our blowers are designed and manufactured according to precise specifications provided by each client, ensuring a seamless fit into existing systems. From dimension customization to application-specific pressure and power ratings, every impeller matches your process demands, resulting in optimal system integration and performance.

Energy Efficient and Easy to Maintain

Equipped with automatic operation and powered by a stable 380-415 Volt supply, this blower consumes energy efficiently. Its Siemens Grey finish, coupled with galvanized treatment, protects against environmental factors, making it easy to maintain and ideal for continuous, heavy-duty industrial applications.

FAQs of Centrifugal Blower MS Impellers:

Q: How does the Centrifugal Blower MS Impeller operate automatically?

A: The centrifugal blower is equipped with built-in automation controls that allow for automatic operation. This ensures consistent airflow management with minimal human intervention, enhancing productivity and operational efficiency.Q: What is the process for customizing dimensions or pressure range?

A: To achieve the ideal fit for your application, provide your specific dimension (L*W*H) and pressure requirements during the order process. Our engineering team then designs and manufactures the impeller according to these exact parameters.Q: Where can these blowers be installed and used?

A: These blowers are suitable for use in various facilities, including chemical processing plants, metal and steel manufacturing environments, and hot air recirculation systems, anywhere industrial-grade air movement is required.Q: What are the benefits of the galvanized surface treatment?

A: The galvanized finish enhances the blowers durability by providing corrosion resistance, ensuring a longer operational life even in harsh industrial settings. This makes maintenance easier and extends equipment longevity.Q: When should maintenance or servicing be performed?

A: Routine maintenance schedules depend on usage intensity, but generally, inspection and basic servicing are recommended every six months. Regular checks help sustain performance and ensure warranty coverage.Q: How is electrical power supplied to the blower?

A: The blower is powered by a standard industrial electricity supply of 380 to 415 Volts, making it compatible with most factory power setups in India and similar international markets.Q: What warranty coverage is provided with these blowers?

A: Each Centrifugal Blower MS Impeller comes with a one-year manufacturers warranty covering any manufacturing defects or operational issues during normal use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spare Impellers Category

DIDW Spare Impellers

Minimum Order Quantity : 1 Number

Warranty : 1 year

Product Type : Other

Color : As per customer requirement

Operating Type : Automatic

Rubber Coated Impellers

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Warranty : 1 year

Product Type : Other

Color : Siemens Grey

Operating Type : Automatic

MS Spare Impeller

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Warranty : 1 year

Product Type : Other

Color : Siemens Grey

Operating Type : Automatic

Rubber Lined Spare Impellers

Price 25000 INR / Unit

Minimum Order Quantity : 1 Set

Warranty : 1 year

Product Type : Other

Color : Siemens Grey

Operating Type : Automatic

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry