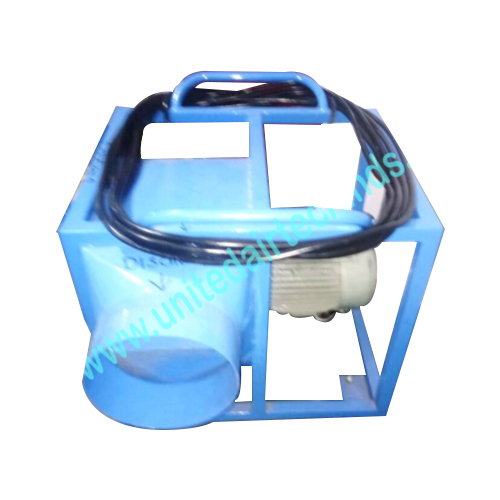

SS316 Centrifugal Blowers

42000.00 - 200000.00 INR/Number

Product Details:

- Output Power As per application Horsepower (HP)

- Pressurization Medium Pressure

- Flow Rate Customer to Specify

- Life Span 10 years

- Pressure Range 100 to 1000 mmwc

- Vaccum Range Customer to Specify Pa

- Max Pressure Customer to Specify ft3/min (CFM)

- Click to View more

X

SS316 Centrifugal Blowers Price And Quantity

- 42000.00 - 200000.00 INR/Number

- 1 Number

SS316 Centrifugal Blowers Product Specifications

- 100 to 1000 mmwc

- 960/1440/2880 RPM

- Centrifugal Blower

- 1 year

- As per design Millimeter (mm)

- Customer to Specify Pa

- As per customer requirement m3/hr

- Electric Blower

- Medium Pressure

- As per the application Horsepower (HP)

- As per the application Kilowatt (kW)

- Siemens Grey

- Customer to Specify ft3/min (CFM)

- Steel

- As per application Horsepower (HP)

- 60 to 85 db

- Customer to Specify

- Industrial, gas analysis

- 10 years

- 415/380/10/230 Volt (v)

- Medium Pressure

- 50/60 Hertz (HZ)

- To be determined as per design Kilograms (kg)

SS316 Centrifugal Blowers Trade Information

- Nhava Sheva Mumbai

- Cash in Advance (CID), Letter of Credit (L/C), Cheque, Cash Advance (CA), Letter of Credit at Sight (Sight L/C)

- 13 Number Per Week

- 10 Days

- Contact us for information regarding our sample policy

- CRATE PACKAGING

- Maharashtra, Karnataka, Madhya Pradesh, Telangana, Andhra Pradesh, Gujarat, Chhattisgarh, Kerala, Rajasthan

- ISO 9001:2015

Product Description

An Industrial Air blower is a blower, whose main function is to supply a huge flow of air or gas to the various processes in the industries. They are electric fans with wheels and blades to drive a current of air or gas from one point to another with certain specifications.

These industrial blowers offer much functionality like combustion, ventilation, aeration, particulate transport, exhaust, cooling, air-cleaning, drying are some of the few. Almost every industry such as agricultural, chemical, medical, oil and gas, automotive, food processing mining and construction use blowers for their specific purpose. Based on the application there are a variety of blowers available in the market. The blower that is purchased should be reliable which runs without issues for a long time and should not generate a lot of noise.

These industrial blowers offer much functionality like combustion, ventilation, aeration, particulate transport, exhaust, cooling, air-cleaning, drying are some of the few. Almost every industry such as agricultural, chemical, medical, oil and gas, automotive, food processing mining and construction use blowers for their specific purpose. Based on the application there are a variety of blowers available in the market. The blower that is purchased should be reliable which runs without issues for a long time and should not generate a lot of noise.

Customizable Performance for Varied Industrial Needs

SS316 Centrifugal Blowers are engineered to cater to unique client requirements. With power, capacity, flow rate, vacuum, and dimensions all specified as per application, they offer broad versatility for sectors like gas analysis, manufacturing, and other industrial uses. Their medium pressure range (1001000 mmwc) and motor speeds up to 2880 RPM ensure they suit both standard and demanding applications effectively.

Durability and Longevity You Can Trust

Manufactured from high-grade steel and finished in Siemens Grey, these blowers deliver consistent performance in challenging conditions. The sturdy build and electric drive system contribute to a 10-year life span, supported by a one-year warranty for added peace of mind. Regular maintenance helps maximize longevity and efficiency.

FAQs of SS316 Centrifugal Blowers:

Q: How can customers specify the appropriate flow rate and vacuum range for their application?

A: Customers are encouraged to provide detailed operational requirements, including desired flow rate (in m3/hr) and vacuum range (in Pa), during the inquiry stage. This allows the manufacturer to tailor blower specifications to suit unique process needs. Engineering support is available to help determine optimal parameters based on the applications demands.Q: What are the primary benefits of using an SS316 Centrifugal Blower in industrial settings?

A: SS316 Centrifugal Blowers provide reliable medium-pressure airflow, long operational life (up to 10 years), and low-to-moderate noise emissions (6085 dB). Their customizable specifications accommodate a wide range of industrial and gas analysis applications, ensuring efficient performance and minimal downtime.Q: When should the blower be serviced for optimal lifespan and performance?

A: To maintain efficiency and prolong the blowers lifespan, routine maintenance should be conducted as per the manufacturers recommendationsthis typically includes regular inspection, cleaning, and monitoring of wear components. Scheduled servicing is especially important in demanding or continuous-operation environments.Q: Where can these blowers be installed, and are there any space requirements?

A: SS316 Centrifugal Blowers are suitable for indoor or semi-sheltered industrial locations. Their dimensions (L*W*H) are designed per customer requirements. Installers should confirm sufficient space for airflow, access, and maintenance when planning installation.Q: What is the process for exporting or supplying these blowers internationally?

A: As an exporter, manufacturer, service provider, and supplier from India, the company offers comprehensive shipping and support for international clients. The process typically starts with a requirements review, followed by manufacturing to custom specifications, and includes documentation, shipment, and after-sales support.Q: How does the electric blower achieve varying pressure and flow rates as per customer requirements?

A: The blowers pressure (1001000 mmwc) and flow rate capabilities are determined by tailoring the impeller design, motor horsepower, and speed (960/1440/2880 RPM) according to customer-supplied parameters. This approach ensures consistent medium-pressure output tailored to each unique application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Centrifugal Blowers' category

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |