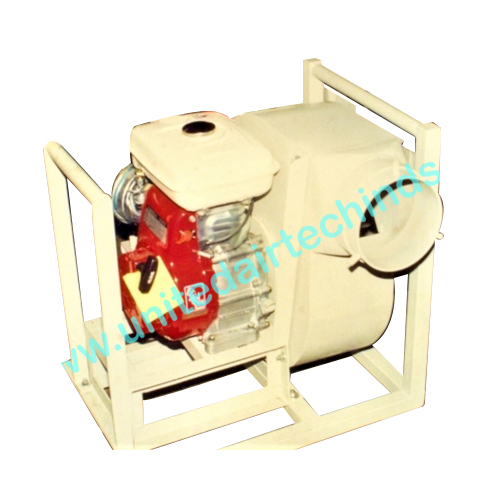

Forced Draft Blowers for Refinery Industries

Product Details:

- Max Pressure Customer to specify m3/hr

- Power As per customer requirment Watt (w)

- Pressure Range 50mmwc to 1000mmwc

- Pressurization high Pressure

- Vaccum Range Customer to specify Pa

- Motor Power As per the application Horsepower (HP)

- Flow Rate Customer to specify

- Click to View more

Forced Draft Blowers for Refinery Industries Price And Quantity

- 1 Number

- 24000.00 - 200000.00 INR/Unit

Forced Draft Blowers for Refinery Industries Product Specifications

- Customer to specify Pa

- 50/60 Hertz (HZ)

- high Pressure

- As per application Horsepower (HP)

- To be determined as per design Kilograms (kg)

- 10 years

- Siemens Grey

- 1440/2880 RPM

- Steel

- As per the application Horsepower (HP)

- Customer to specify

- As per design Millimeter (mm)

- Industrial

- 415/380/230/110 Volt (v)

- 1 year

- Customer to specify m3/hr

- Customer to specify m3/hr

- Centrifugal Blower

- 60 to 85 db

- Electric Blower

- High Pressure

- As per customer requirment Watt (w)

- 50mmwc to 1000mmwc

Forced Draft Blowers for Refinery Industries Trade Information

- Nhava Sheva Mumbai

- Paypal Letter of Credit (L/C) Western Union Letter of Credit at Sight (Sight L/C) Cash in Advance (CID) Cheque

- 3 Number Per Week

- 4 Week

- Contact us for information regarding our sample policy

- Crate Packing

- Australia North America South America Eastern Europe Western Europe Middle East Central America Asia Africa

- All India

- ISO 9001:2015

Product Description

The vapor recovery process is based on activated carbon bed adsorption and regeneration of carbon by means of vaccum.

The Vapour Recovery Systems based on CESs technology are considered to be the best available technology in the market by many of the world's leading oil and liquid storage companies.

The vapour recovery process of CES consists of very simple 3 steps technology:

- Adsorption of hydrocarbon on activated carbon bed.

- Regeneration of carbon bed by means of vacuum.

- Re-absorption of hydrocarbon into liquid product.

Normally two adsorbers, a simple dry vacuum system, an absorber and two absorbent circulation pumps thus makeup a complete operational system of vapour recovery.

The standard system can be used for wide range of chemical and petroleum products with highly variable compositions, concentrations and flow rate

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Centrifugal Blowers' category

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |