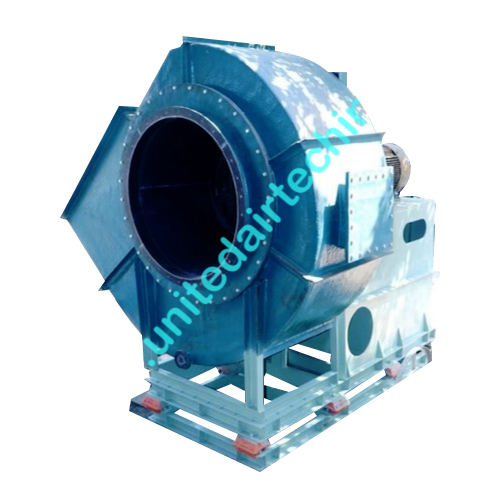

Industrial Centrifugal blower

Price 30000 INR/ Unit

MOQ : 1 Set

Industrial Centrifugal blower Specification

- Max Pressure

- Customer to Specify ft3/min (CFM)

- Output Power

- As per application Horsepower (HP)

- Pressure Range

- 100 to 1000 mmwc

- Life Span

- 10 years

- Motor Power

- As per the application Kilowatt (kW)

- Flow Rate

- Customer to Specify

- Power

- As per the application Horsepower (HP)

- Vaccum Range

- 100 to 1000 mmwc Pa

- Pressurization

- Medium Pressure

- Product Type

- Centrifugal Blower

- Material

- Steel

- Capacity

- As per customer requirement m3/hr

- Pressure

- Medium Pressure

- Frequency (MHz)

- 50/60 Hertz (HZ)

- Motor Speed

- 960/1440/2880 RPM

- Noise Level

- 60 to 85 db

- Power Source

- Electric Blower

- Voltage

- 415/380/10/230 Volt (v)

- Weight

- To be determined as per design Kilograms (kg)

- Dimension (L*W*H)

- As per design Millimeter (mm)

- Color

- Siemens Grey

- Warranty

- 1 year

Industrial Centrifugal blower Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Nhava Sheva Mumbai

- Payment Terms

- Cash in Advance (CID), Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA)

- Supply Ability

- 10 Sets Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- CRATE PACKAGING

- Main Domestic Market

- Chhattisgarh, Maharashtra, Andhra Pradesh, Telangana, Gujarat, Rajasthan, Madhya Pradesh, Karnataka, Kerala

- Certifications

- ISO 9001:2015

About Industrial Centrifugal blower

An Industrial Air blower is a blower, whose main function is to supply a huge flow of air or gas to the various processes in the industries. They are electric fans with wheels and blades to drive a current of air or gas from one point to another with certain specifications.These industrial blowers offer much functionality like combustion, ventilation, aeration, particulate transport, exhaust, cooling, air-cleaning, drying are some of the few. Almost every industry such as agricultural, chemical, medical, oil and gas, automotive, food processing mining and construction use blowers for their specific purpose. Based on the application there are a variety of blowers available in the market. The blower that is purchased should be reliable which runs without issues for a long time and should not generate a lot of noise.

Precision Engineering for Tailored Applications

Our centrifugal blowers are meticulously designed according to the clients operational and dimensional needs. Whether its the horsepower, capacity in m3/hr, or a particular pressure range, every element is adapted to ensure ideal performance for applications ranging from gas analysis to broad industrial processes.

Durability and Efficiency Combined

Constructed from high-quality steel and coated in Siemens Grey, our blowers deliver longevity with minimal maintenance. With a projected lifespan of 10 years and a reliable one-year warranty, users benefit from consistent operation, reduced downtime, and peace of mind.

Versatile Power Configurations

Operating from 230 to 415 volts and 50/60 Hz frequencies, the centrifugal blower easily integrates with diverse industrial power systems. Motor speed options, including 960, 1440, and 2880 RPM, and customized output power ensure that specific airflow and pressure requirements are met precisely.

FAQs of Industrial Centrifugal blower:

Q: How do I specify the correct flow rate and pressure for my application?

A: You can define your required flow rate and maximum pressure during the inquiry or ordering process. The design team will consult with you to understand your process requirements and recommend a blower with the appropriate capacity, measured in m3/hr or CFM, and pressure specifications.Q: What are the typical industrial uses for this centrifugal blower?

A: These blowers are commonly used in gas analysis, ventilation, material handling, and other medium-pressure industrial processes. Their robust build and customizability make them suitable for a wide range of industries.Q: When should periodic maintenance be performed on the blower?

A: Routine maintenance, such as checking bearings, cleaning the impeller, and verifying electrical connections, should be carried out according to the operational environmenttypically every six months for optimal performance and longevity.Q: Where is this blower manufactured and supplied from?

A: We manufacture, export, supply, and provide services for our centrifugal blowers from our facilities in India, with delivery and support available domestically and internationally.Q: What is the process to order a customized blower?

A: To order, provide your application details including desired flow rate, pressure, power requirements, and spatial constraints. Our engineers will design a tailored solution, confirm specifications, and initiate production post-approval.Q: How does this blower benefit my operation compared to standard models?

A: Customizable design, medium pressure efficiency, electric operation, and a 10-year lifespan provide tailored performance, reduced downtime, and long-term cost savings, adding significant value to your industrial processes.Q: What warranty and after-sales support are available?

A: Each blower comes with a 1-year warranty. Our service team offers ongoing technical support and maintenance guidance to ensure sustained performance throughout the products life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Centrifugal Blowers Category

Large Air Capacity Blower Fan

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Siemens Grey

Weight : To be determined as per design Kilograms (kg)

Warranty : 1 year

Voltage : 415/230/380/110 Volt (v)

PVC Centrifugal Blower

Minimum Order Quantity : 1 Unit

Color : AS PER CUSTOMER

Weight : As per requirement and application Kilograms (kg)

Warranty : 1 YEAR

Voltage : 230380/415/440 Volt (v)

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry