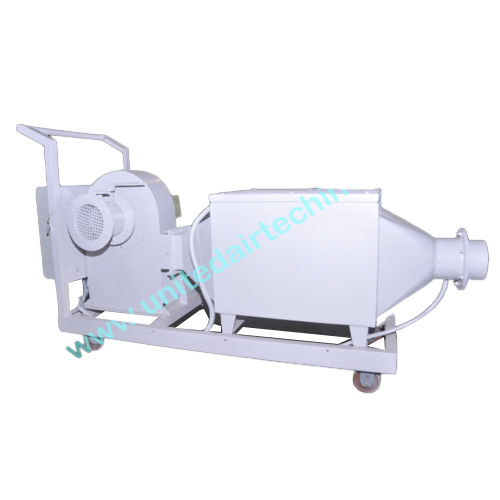

High Temperature Fan Unit

Price 40000 INR/ Number

High Temperature Fan Unit Specification

- Capacity

- As per customer requirement m3/hr

- Frequency (MHz)

- 50/60 Hertz (HZ)

- Motor Speed

- 960/1440/2880 RPM

- Voltage

- 230/380/415/440 Volt (v)

- Weight

- As per design data Kilograms (kg)

- Dimension (L*W*H)

- As per customer requirement Millimeter (mm)

- Color

- Siemens Grey

- Warranty

- 1 year

High Temperature Fan Unit Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1 Set Per Week

- Delivery Time

- 8 Days

- Main Export Market(s)

- North America, Eastern Europe, Middle East, Australia, Central America, Asia, Africa, Western Europe, South America

- Main Domestic Market

- Karnataka, Rajasthan, Maharashtra, Gujarat, Madhya Pradesh, Chhattisgarh, Kerala, Andhra Pradesh, Telangana

About High Temperature Fan Unit

Empowered with a squad of enthusiastic personnel, we have been able to offer a broad assortment ofHot Air Systemin varied technical applications. Offered system is manufacture using the best quality raw material and is also well-tested on defined parameters. This system is used for quick drying of narrow necked glassware, round bottom flasks, bottles, conical flasks and pipettes. Clients can avail thisHot Air Systemfrom us at market leading prices.

Products Features:

- Sturdy construction

- Optimum performance

- High efficiency

- Longer service life

Products Specifications:

Our Hot Air System incorporates advanced hot air generator, which powers the hot filtered air into hydraulic circuit. The generator is fitted to power the hot-filtered air into a washed chamber. Hot-filtered air is provided to the internal hydraulic circuits by this system. This process directs the jet on materials internal surfaces, and the material is washed through the spigots of direct injection system trolleys. Hot air maximum temperature is : 100C, and drying time can be adjusted from 10 - 60 minutes & the temperature from 60C - 100C, in 30 programs. And the drying system is quick & efficient for drying of round bottom flasks, narrow necked glassware, pipettes and conical flasks etc. Humidity is quickly & easily eliminated, by virtue of the direct injection on to internal surfaces.

Customised for Your Application

The High Temperature Fan Unit is designed to deliver dependable performance in challenging settings. With tailorable dimensions and capacity, it addresses specific airflow requirements, especially in areas subject to elevated temperatures. Its versatility makes it suitable for numerous industrial processes, including foundries and heat-intensive production lines.

Durability Meets Efficiency

Finished in Siemens Grey, this fan unit assures both aesthetic harmony and resistance to rigorous operating conditions. The sturdy construction and adaptable motor speeds improve efficiency, while the units reliability is backed by a comprehensive one-year warranty, ensuring peace of mind for operators.

FAQs of High Temperature Fan Unit:

Q: How can customers specify the dimensions for the High Temperature Fan Unit?

A: Customers can provide precise length, width, and height requirements in millimeters upon order placement. This allows for a fully customized fan unit that fits seamlessly into their existing infrastructure.Q: What is the process for installation and commissioning the fan unit?

A: Once delivered, the installation process is guided by detailed instructions provided by our team. Technical support and commissioning services are available to ensure optimal setup and safe operation at your facility.Q: When should this fan unit be used in industrial applications?

A: The unit is best utilized in environments where high temperatures, variable airflow, and flexible capacity are required, such as furnaces, foundries, or chemical plants requiring robust air movement.Q: Where is this fan unit manufactured and shipped from?

A: The High Temperature Fan Unit is manufactured in India and can be shipped nationally or internationally as per the clients needs, supported by our network as exporter and supplier.Q: What are the benefits of using this fan unit in high-temperature settings?

A: This fan unit is specifically engineered to endure elevated temperatures while maintaining consistent performance. Its customization, multiple voltage options, and durable build offer reliability and improved process efficiency.Q: How does the warranty work for this product?

A: Each High Temperature Fan Unit comes with a one-year warranty covering manufacturing defects and operational failures, providing confidence and support for your investment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Air Centrifugal Blowers Category

Hot Air Centrifugal Blower Unit

Price 40000 INR / Set

Minimum Order Quantity : 1 Set

Warranty : 1 year

Motor Speed : 960/1440/2880 RPM

Voltage : 230/380/415/440 Volt (v)

Color : Siemens Grey

SS Centrifugal Blower Hot Air Unit

Price 34000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 YEAR

Motor Speed : 960/1440/2880 RPM

Voltage : 230380/415/440 Volt (v)

Color : AS PER CUSTOMER

Hot Air Blower Portable Type

Price 40000 INR / Number

Minimum Order Quantity : 1 Set

Warranty : 1 year

Motor Speed : 960/1440/2880 RPM

Voltage : 230/380/415/440 Volt (v)

Color : Siemens Grey

Hot Air Centrifugal Blower Unit Upto 300 Deg C

Minimum Order Quantity : 1 Set

Warranty : 1 year

Motor Speed : 960/1440/2880 RPM

Voltage : 230/380/415/440 Volt (v)

Color : Siemens Grey

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry