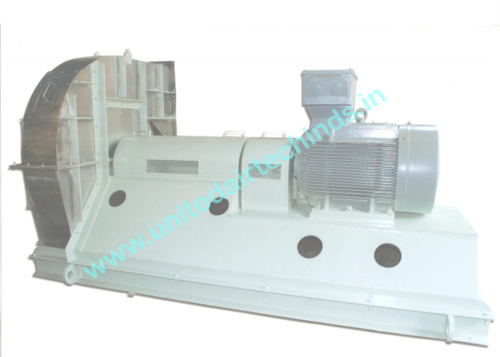

Forced Draft Blowers for Refinery Industries

Forced Draft Blowers for Refinery Industries Specification

- Flow Rate

- Customer to specify

- Pressure Range

- 50mmwc to 1000mmwc

- Motor Power

- As per the application Horsepower (HP)

- Vaccum Range

- Customer to specify Pa

- Output Power

- As per application Horsepower (HP)

- Pressurization

- high Pressure

- Life Span

- 10 years

- Power

- As per customer requirment Watt (w)

- Max Pressure

- Customer to specify m3/hr

- Product Type

- Centrifugal Blower

- Material

- Steel

- Capacity

- Customer to specify m3/hr

- Pressure

- High Pressure

- Frequency (MHz)

- 50/60 Hertz (HZ)

- Motor Speed

- 1440/2880 RPM

- Noise Level

- 60 to 85 db

- Power Source

- Electric Blower

- Voltage

- 415/380/230/110 Volt (v)

- Weight

- To be determined as per design Kilograms (kg)

- Dimension (L*W*H)

- As per design Millimeter (mm)

- Color

- Siemens Grey

- Warranty

- 1 year

Forced Draft Blowers for Refinery Industries Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Nhava Sheva Mumbai

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cheque

- Supply Ability

- 13 Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- CRATE PACKAGING

- Main Domestic Market

- Chhattisgarh, Rajasthan, Kerala, Telangana, Karnataka, Madhya Pradesh, Maharashtra, Gujarat, Andhra Pradesh

- Certifications

- ISO 9001:2015

About Forced Draft Blowers for Refinery Industries

The vapor recovery process is based on activated carbon bed adsorption and regeneration of carbon by means of vaccum.

The Vapour Recovery Systems based on CESs technology are considered to be the best available technology in the market by many of the worlds leading oil and liquid storage companies.

The vapour recovery process of CES consists of very simple 3 steps technology:

- Adsorption of hydrocarbon on activated carbon bed.

- Regeneration of carbon bed by means of vacuum.

- Re-absorption of hydrocarbon into liquid product.

Normally two adsorbers, a simple dry vacuum system, an absorber and two absorbent circulation pumps thus makeup a complete operational system of vapour recovery.

The standard system can be used for wide range of chemical and petroleum products with highly variable compositions, concentrations and flow rate

High Customizability for Diverse Applications

Our Forced Draft Blowers are precisely tailored to meet specific industrial needs in refinery sectors. With flow rates, pressure ranges, and capacities determined as per customer instructions, these blowers promise adaptability and optimized performance, regardless of unique operational challenges.

Long Lifespan and Reliable Operation

Built from high-grade steel and designed for durability, each blower boasts a lifespan of up to 10 years and features Siemens Grey protective coating. This ensures reliable operation even under demanding refinery conditions, minimizing downtime and maintenance costs.

Performance and Efficiency

Powered by energy-efficient electric motors, our blowers offer high motor speeds (1440/2880 RPM) and support various voltages and power outputs according to your application. The units maintain low operational noise and deliver consistent high-pressure airflow, contributing to smooth plant processes.

FAQs of Forced Draft Blowers for Refinery Industries:

Q: How are Forced Draft Blowers used in refinery industries?

A: Forced Draft Blowers are crucial in refinery processes for supplying high-pressure air to combustion systems and various other industrial operations that require controlled airflow. They ensure efficient fuel burning and process stability by maintaining the necessary air volume and pressure.Q: What options are available for pressure and flow rate with these blowers?

A: Both pressure (ranging from 50 mmwc to 1000 mmwc) and flow rate (capacity and maximum pressure) are fully customizable based on customer specifications. This flexibility allows the blowers to meet a wide range of performance requirements in industrial settings.Q: When should customers specify key parameters like flow rate, capacity, and vacuum range?

A: Customers are advised to provide their specific requirements for flow rate, capacity, max pressure, and vacuum range at the inquiry or ordering stage. This information ensures that the blower is engineered and manufactured to precisely fit your operational needs.Q: Where can these Forced Draft Blowers be installed within refinery plants?

A: These blowers are designed for installation in various sections of refinery industries, including furnace combustion systems, exhaust management, and any process area that demands controlled air movement and pressurization.Q: What is the typical process for ordering a customized Forced Draft Blower?

A: The process begins with customers detailing their specific requirementssuch as flow rate, pressure, dimensions, and power needs. Our engineering team then designs the blower to these specifications for optimum integration into your facility.Q: What are the benefits of choosing your Forced Draft Blowers for refinery applications?

A: Benefits include highly customizable performance parameters, reliable long-term operation, energy-efficient electric motors, low noise levels, and robust steel construction. Our blowers also come with a 1-year warranty and the support of a trusted Indian manufacturer and exporter.Q: How does the warranty and after-sales service work for these blowers?

A: Each blower comes with a 1-year warranty covering manufacturing defects. Our service team provides both on-site and remote support to ensure the long-term efficiency and performance of every installed unit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Centrifugal Blowers Category

Centrifugal Blower

Price 20000.00 INR / Piece

Minimum Order Quantity : 3 Pieces

Capacity : As per application m3/hr

Product Type : Centrifugal Blower

Warranty : 1 YEAR

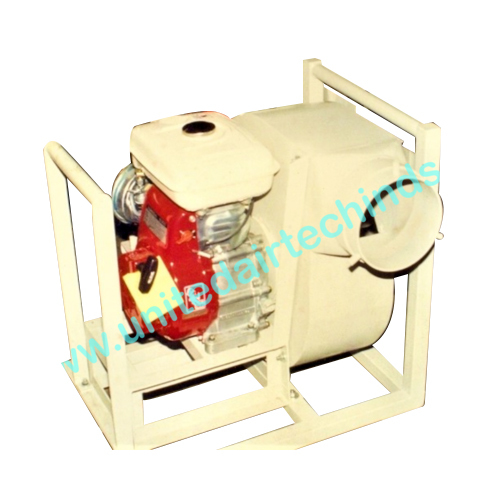

Engine Driven Portable Blowers

Price Range 12000.00 - 52000.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Customer to specify m3/hr

Product Type : Centrifugal Blower

Warranty : 1 year

SS304 Medium Capacity Centrifugal Air Blower

Price Range 55000.00 - 250000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : As per customer application m3/hr

Product Type : Centrifugal Blower

Warranty : 1 YEAR

Centrifugal Blower Coupling Drive

Price 58000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : As per customer specs m3/hr

Product Type : Centrifugal Blower

Warranty : 1 YEAR

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry