Centrifugal Blowers For Paint Booth Applications

Centrifugal Blowers For Paint Booth Applications Specification

- Life Span

- Lifelong

- Pressure Range

- Depending on the application

- Motor Power

- As per customer requirement Horsepower (HP)

- Flow Rate

- Depending on the application

- Power

- As per customer requirment Watt (w)

- Pressurization

- Medium Pressure

- Vaccum Range

- Depending on the application Pa

- Max Pressure

- 25000 m3/hr

- Product Type

- Centrifugal Blower

- Material

- Steel

- Capacity

- As per customer requirement m3/hr

- Pressure

- Medium Pressure

- Application

- Industrial, Air knives, Packing, Soil remediation, Food-processing, prinitng, textile, gas analysis, Dental

- Frequency (MHz)

- 50 Hertz (HZ)

- Motor Speed

- As per customer requirement & standard motor sizes RPM

- Noise Level

- 85 db

- Power Source

- Electric Blower

- Voltage

- 415 Volt (v)

- Color

- AS PER CUSTOMER

- Warranty

- 1 year

Centrifugal Blowers For Paint Booth Applications Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva Mumbai

- Payment Terms

- Cash in Advance (CID), Letter of Credit (L/C), Cheque, Cash Advance (CA), Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 13 Units Per Week

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- CRATE PACKAGING

- Main Domestic Market

- Rajasthan, Kerala, Chhattisgarh, Andhra Pradesh, Gujarat, Karnataka, Madhya Pradesh, Maharashtra, Telangana

- Certifications

- ISO 9001:2015

About Centrifugal Blowers For Paint Booth Applications

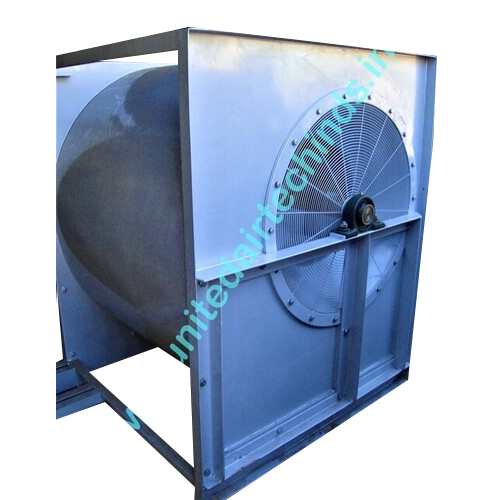

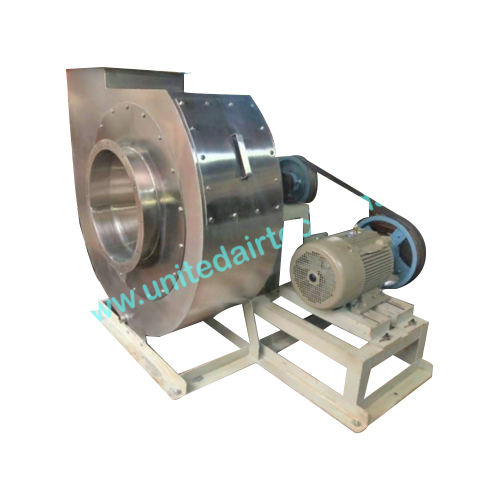

Centrifugal Blowers For Paint Booth Applications

Centrifugal blowers are used in paint shop & booths to collect the paint particles in the air and exhaust it to the atmosphere. Paint shop blowers are mostly Centrifugal Industrial Air Blowers.

Selection Appropriate paint booth blowers selection is important for Superior paint quality Clean working environment as per Industrial norms To reduce concentration of fumes in air, below lower explosive limits inside the shop.

Engineered for Versatility

Our centrifugal blowers are crafted for a wide range of industrial applications. They excel in environments such as paint booths, packing lines, food processing plants, and textile industries. The adaptability in flow rate, pressure range, and motor power allows seamless integration into diverse operational setups. Each unit is manufactured to match specific requirements, ensuring both efficient air movement and dependable service life for critical processes.

Customizable to Your Needs

Every blower can be tailored with capacities, pressure ranges, and motor speeds to suit your exact application. From color selection to volume output and electric power requirements, our solutions provide maximum flexibility. Whether you require higher flow for large-scale soil remediation or medium pressure for precision air knives, we ensure optimal performance while matching your facilitys standards.

Reliable Performance and Lifelong Durability

Designed with premium steel and engineered for enduring performance, our blowers operate efficiently even under rigorous industrial conditions. They are built for medium-pressure requirements and deliver high volume throughput while maintaining noise below 85 dB. Backed by a 1-year warranty and a lifelong lifespan, these blowers promise both peace of mind and sustained reliability, minimizing maintenance downtime.

FAQs of Centrifugal Blowers For Paint Booth Applications:

Q: How do I determine the correct centrifugal blower specification for my paint booth application?

A: Choosing the right blower depends on required flow rate, pressure range, and specific industrial use. Our experts will assess your application detailssuch as booth size, air change requirements, and volume neededand customize the blower with suitable motor power, speed, and capacity to ensure optimal performance.Q: What materials are used in constructing the blowers, and what benefits do they offer?

A: Our centrifugal blowers are manufactured from high-quality steel, ensuring robust construction, corrosion resistance, and long-lasting durability even in demanding industrial environments. This material choice supports a lifelong operational lifespan and consistent airflow.Q: When should centrifugal blowers be serviced or maintained?

A: Routine maintenance is recommended in accordance with your operational hours and environmental conditions. Regular checks on motor integrity, bearing lubrication, and filter cleanliness help maintain efficiency and prolong the blowers lifespan. Our products are designed for easy servicing and come with a 1-year warranty.Q: Where can these blowers be used beyond paint booths?

A: These blowers serve multiple industries including food processing, soil remediation, textiles, dental labs, printing, packing, and gas analysis. Their adaptability in flow and pressure makes them suitable for both general ventilation and specialized air movement tasks.Q: What is the process for customizing a blower to my facilitys requirements?

A: Customization begins with an assessment of your specific application needs, such as required air volume, pressure, electrical supply, and usage environment. Our team collaborates to design and deliver a blower with tailored motor power, speed, color, and other features that match your operational preferences.Q: How does the medium pressure capability benefit industrial applications?

A: Medium pressure blowers strike a balance between high flow and manageable energy consumption, making them ideal for processes that require strong but controlled air movement. This ensures efficient debris removal, drying, or recirculation in applications such as air knives and food processing.Q: What noise levels should I expect during operation?

A: Our centrifugal blowers are engineered to operate at a maximum noise level of 85 dB, which is suitable for most industrial environments. Proper installation and regular maintenance can help manage and further reduce operational sound.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Centrifugal Blowers Category

Compact Portable Blower

Price 34000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : As per customer requirement m3/hr

Warranty : 1 year

Color : Siemens Grey

DIDW Centrifugal Blowers

Price Range 34000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Set

Capacity : As per customer specs Kiloliter/day

Warranty : 1 year

Color : AS PER CUSTOMER

Medium Pressure Air Blowers

Price Range 34000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : As per customer specs Kg/hr

Warranty : 1 year

Color : Siemens Grey

High Pressure Industrial Blowers

Price 58000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : As per customer specs Kg/hr

Warranty : 1 Year

Color : As per customer

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry