Ship Deck Axial Flow Fans

Product Details:

- Revolution NA

- Power Consumption Customer to specify Kilowatt (kW)

- Pressure 50 to 350 mmwc Pa

- Voltage 415 Volt (v)

- Speed 750/960/1440/2880 RPM

- Air Volume Customer to specify m3/hr

- Noise Level less than 85 dB db

- Click to View more

Ship Deck Axial Flow Fans Price And Quantity

- 1 Number

- 18000.00 - 126000.00 INR/Number

Ship Deck Axial Flow Fans Product Specifications

- Siemens Grey

- less than 85 dB db

- Axial

- 1 year

- Ship deck

- Customer to specify Kilowatt (kW)

- Tube Axial

- Customer to specify Millimeter (mm)

- Customer to specify

- Customer to specify Millimeter (mm)

- NA

- Customer to specify Millimeter (mm)

- Round/ Square

- 415/380/230/110 Volt (v)

- 750/960/1440/2880 RPM

- 415 Volt (v)

- Electric

- Customer to specify m3/hr

- To be determined as per design Kilograms (kg)

- 50 to 350 mmwc Pa

- Aluminum Alloy

Ship Deck Axial Flow Fans Trade Information

- Nhava Sheva Mumbai

- 10 Number Per Week

- 1 Week

- CRATE PACKAGING

- Gujarat, Madhya Pradesh, Telangana, Kerala, Karnataka, Maharashtra, Chhattisgarh, Andhra Pradesh, Rajasthan

- ISO 9001:2015

Product Description

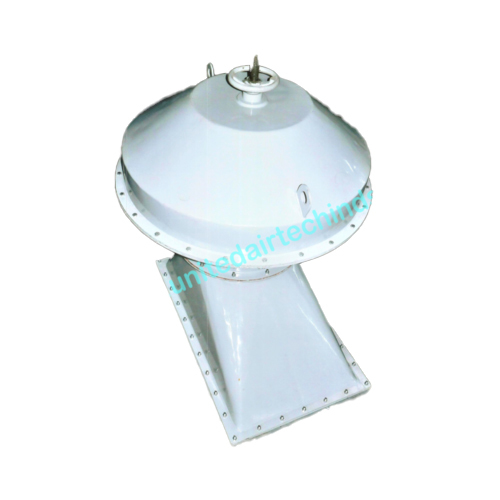

DESIGN

These fans are designed primarily for ventilation, both supply and extraction, of pump-rooms and other places where explosive fumes occur. The fan is spark proof with a totally enclosed, natural cooled and flameproof electric motor. Long experience has contributed to a simple construction with only one rotating part in addition to the motor itself. The propeller is mounted directly to the motor shaft, thus making it one unit with the motor flange which

can be lifted out for inspection.

EXECUTION

Fan casing consists of welded steel plates of heavy duty design. The impeller is made of salt- and ammonia resistant aluminium die caste. Aerodynamically shaped and balanced.

The wings can be inserted at various pitch angles to suit specified capacities and pressures. The mesh guard is made of stainless steel. Greasing-point for gas tight assembly is provided on top of the cowl. These fans can be de-livered in the range from size no 260 to size no 1250.

ELECTRIC MOTOR

The motor is totally enclosed, natural cooled and flameproof, designed for above deck

mounting. Test certificates are delivered with each motor.

CLASSIFICATION SOCIETIES

The fan satisfy the demands of the various classification societies.

ACCESSORIES

- Counter flange

- Protection grid

Customizable Airflow Solutions for Ship Decks

Our axial flow fans are designed to accommodate customer-specific requirements, including air volume, flow rate, pressure, and physical dimensions. Whether your project calls for a round or square shape, or a particular motor speed and power, these fans adapt seamlessly to ship deck infrastructures, ensuring optimal performance and energy efficiency.

Durable Construction for Marine Environments

Manufactured with corrosion-resistant aluminum alloy blades and finished in Siemens Grey, these fans are built to withstand harsh maritime conditions. The robust design extends the products life span to 10 years, supporting continuous operation onboard. We offer flexible options for voltage and shape to fit diverse ship deck installations.

FAQs of Ship Deck Axial Flow Fans:

Q: How do I specify the air volume and flow rate requirements for my ship deck axial flow fan?

A: Customers can provide their air volume (m3/hr or CFM) and flow rate requirements during the inquiry or order process. Our engineering team will assist in selecting the optimal fan configuration based on these parameters and your specific application needs.Q: What is the noise level of these axial flow fans during operation?

A: These fans operate with a noise level ranging between 60 to 85 dB, always remaining below the 85 dB threshold to minimize disturbance and ensure a comfortable environment onboard.Q: What materials are used in the construction of ship deck axial flow fans?

A: The fans are constructed with high-quality aluminum alloy blades and other durable materials, specifically chosen to resist corrosion and endure the challenging marine atmosphere.Q: Where are Ship Deck Axial Flow Fans typically installed on a vessel?

A: These fans are installed on ship decks to facilitate efficient ventilation and air circulation, supporting a healthy and safe environment for crew and sensitive equipment.Q: What type of warranty and after-sales support is provided for these fans?

A: We offer a 1-year warranty from the date of purchase, covering manufacturing defects. Our service provider network in India ensures prompt support and maintenance when needed.Q: What benefits do medium pressure axial fans offer on ship decks?

A: Medium pressure axial fans deliver reliable airflow suitable for ventilation needs, optimizing air exchange rates while maintaining energy efficiency. Their design supports both round and square installations as per deck requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Tube Axial Fans' category

|

UNITED AIR TECH INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |